Services

Process Safety Management

Our Process Safety Management capabilities are as follows:

01. Reactive Pressure Relief System Design

02. Process Hazard Analysis

03. Quantitative Risk Assessment

04. Kinetic Modeling

Incident Investigation & Failure Analysis

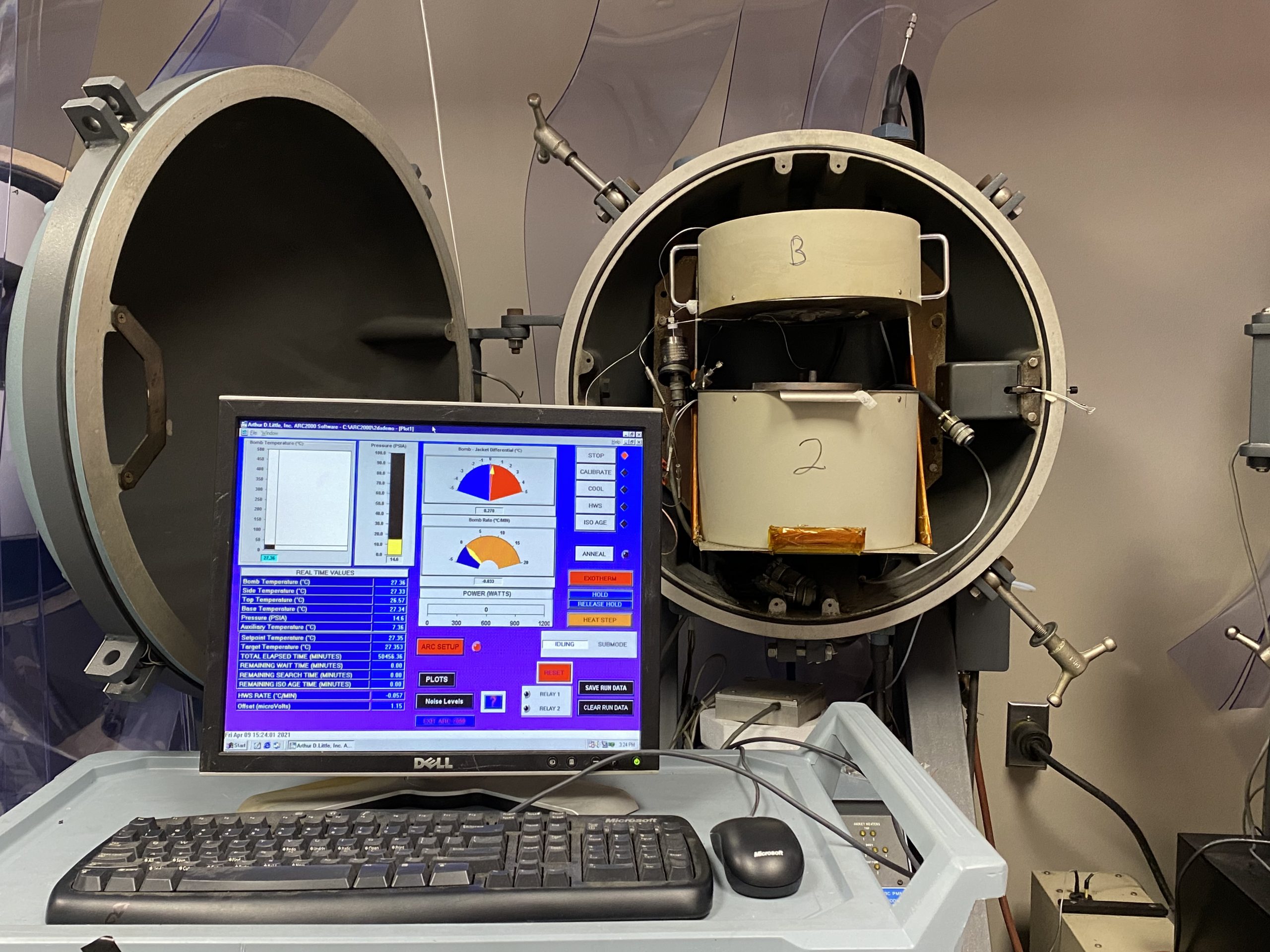

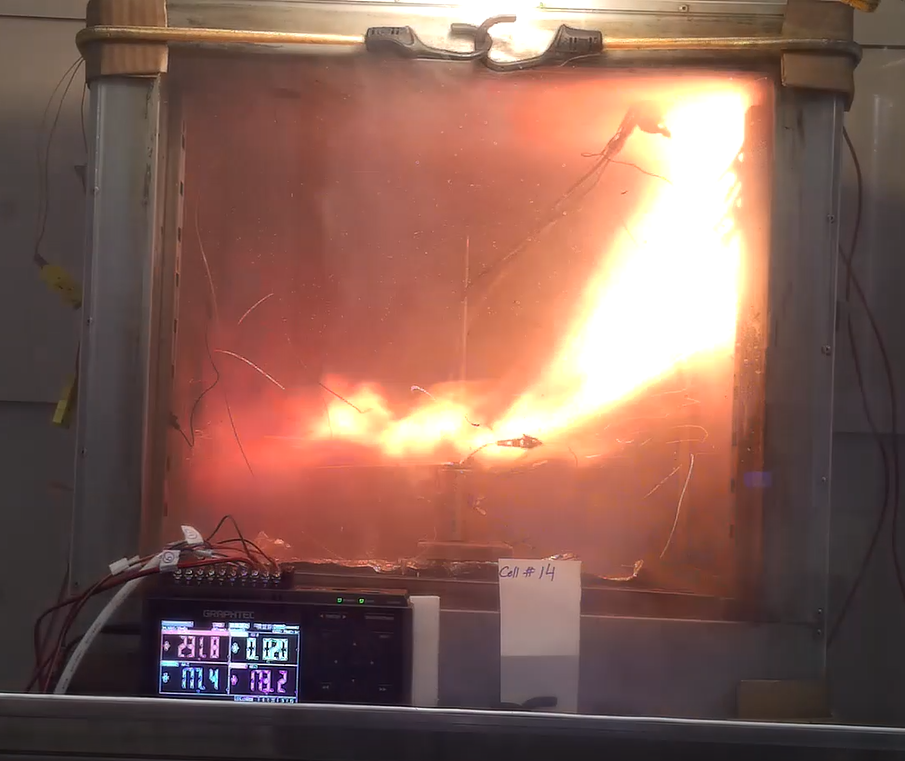

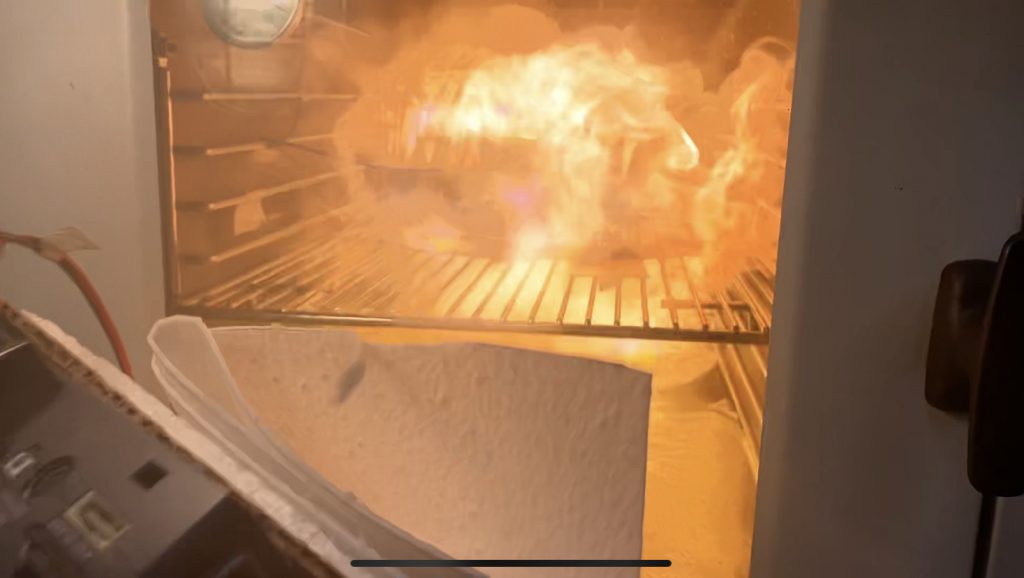

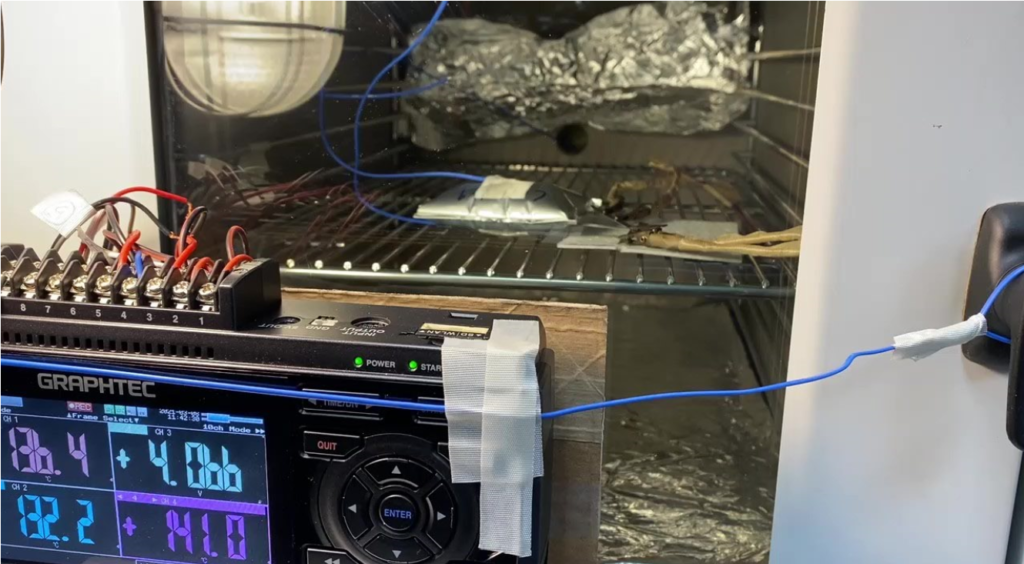

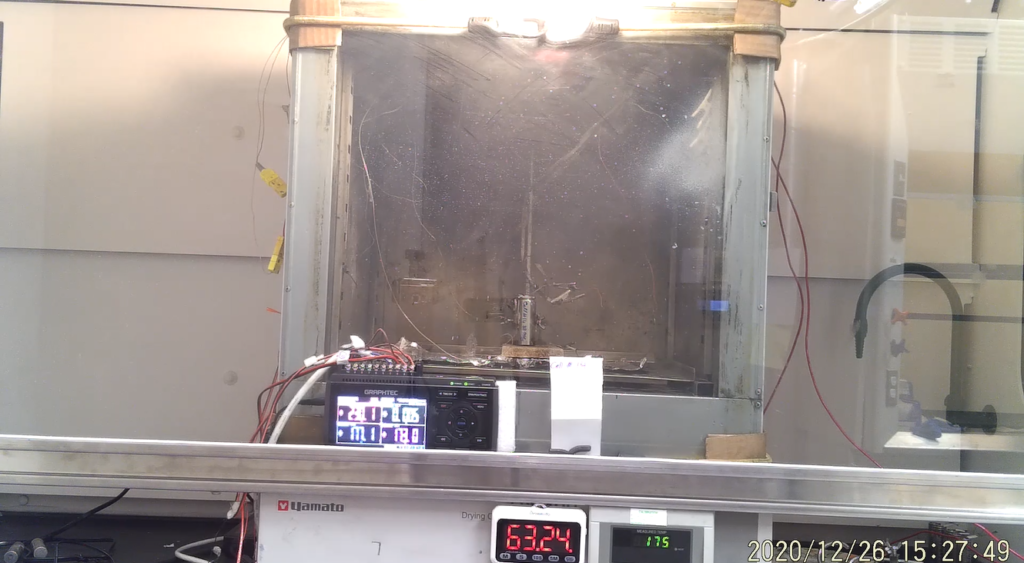

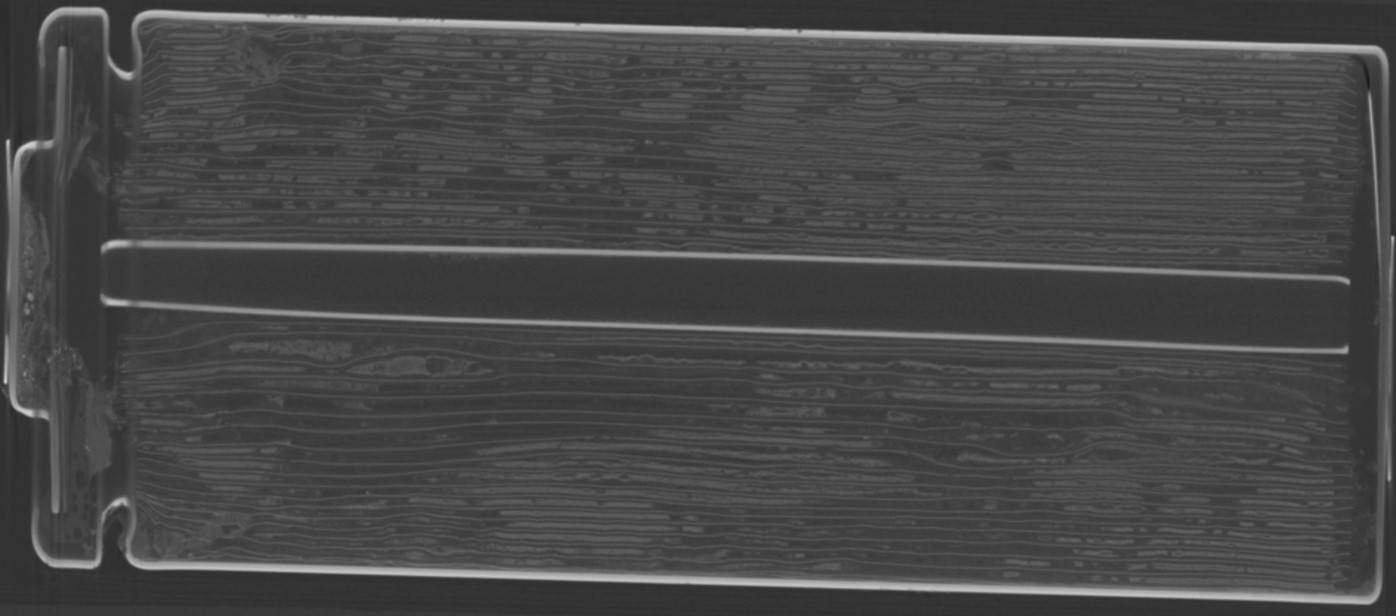

Our experts have conducted root cause failure analyses of cells and battery packs used in laptops, power tools, HEV cells, cell phones, and other consumer electronics. This work was done on several battery chemistries (Li-ion, Li-polymer, Lead acid, Nickel metal hydride, and Alkaline) and designs (cylindrical, prismatic, pouch, and coin cells). During the late 1990’s and early 2000’s, our experts worked with major laptop and Li-ion cell manufacturers to find the root cause of these failures. Various issues were found such as improper winding of the jelly roll, uneven coatings, unbalanced effective electrode mass, and foreign contaminant particles. This study found that two of the major causes of cell failure were the presence of contaminants and spot welding of the current collector.

Training

Belmont Scientific offers training in the following areas:

- Chemical reactivity and calorimetry

- Pressure relief system design

- Process hazard analysis

- Dust hazard analysis

- Battery design and performance evaluation

- Thermal hazard evaluation of batteries

- Root cause failure analysis of batteries

Litigation Support

Belmont Scientific, Inc. is an independent research and testing laboratory which provides unbiased, technical answers for engineering litigation matters so that you can map out your case with confidence. The BSI team possesses technical expertise and experience in the design and operation of batteries used in consumer goods, electric vehicles, battery energy storage systems (BESS) and medical devices.

Latest Case Studies

ADDRESS

- +1 (978) 677 - 9671

- info@belmontscientific.com

- 210 Stedman Street,Unit 3 Lowell,MA 01851,USA