Chemical Reactivity

Chemical Reactivity

In order to run a safe manufacturing process, it is critical to understand the individual reactions within the process. These reactions can be exothermic or endothermic, each of which can be hazardous. These reactions could be a part of the desired chemistry of the process. However, these reactions could also be caused by undesired chemistry such as side reactions. Environmental changes can also result in undesired chemistry. Therefore, identification and assessment of these reactions is important especially during the scaleup of an operation. Belmont Scientific provides cost effective testing which is listed in the table below.

Properties Measured/Estimated

Standard or Test Technique

Key Test/Instrument

Onset temperature

Heat flow rate

Heat of melt

Latent heat of evaporation

Melting/boiling temperature

Enthalpy of endotherm

Enthalpy of exotherm

ASTM E537

Standard Test Method for the Thermal Stability of Chemicals by Differential Scanning Calorimetry (DSC)

Standard Test Method for the Thermal Stability of Chemicals by Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimeter (DSC) by TA Instrument

Heat capacity

ASTM E1269

Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimeter (DSC)

Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimeter (DSC)

Differential Scanning Calorimeter (DSC) by TA Instrument

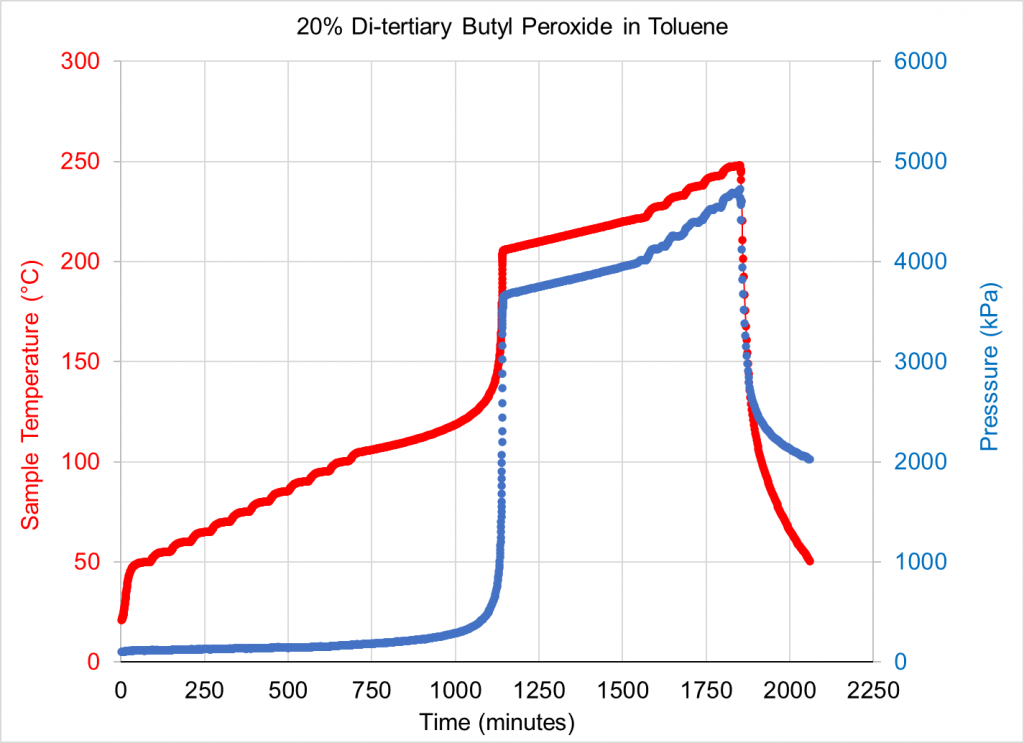

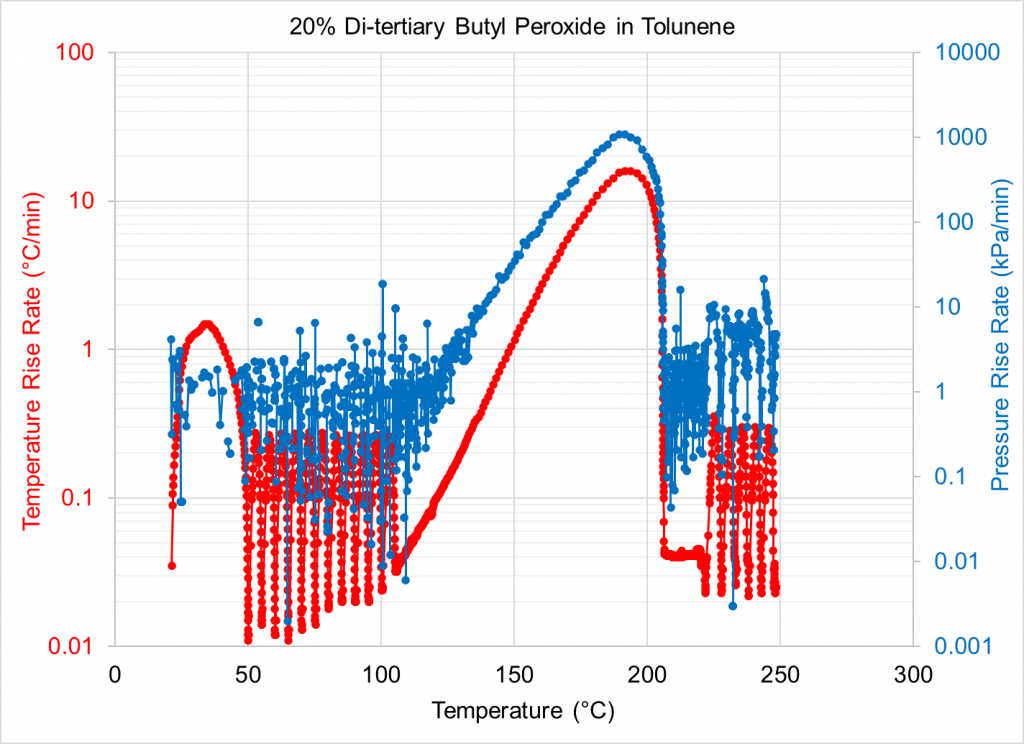

Onset temperature

Temperature rise rate

Pressure rise rate

Heat of reaction

Amount of gas generated

ASTM E1981-98 (2012)e1

Standard Guide for Assessing Thermal

Stability of Materials by Method of

Accelerating Rate Calorimetry (ARC)

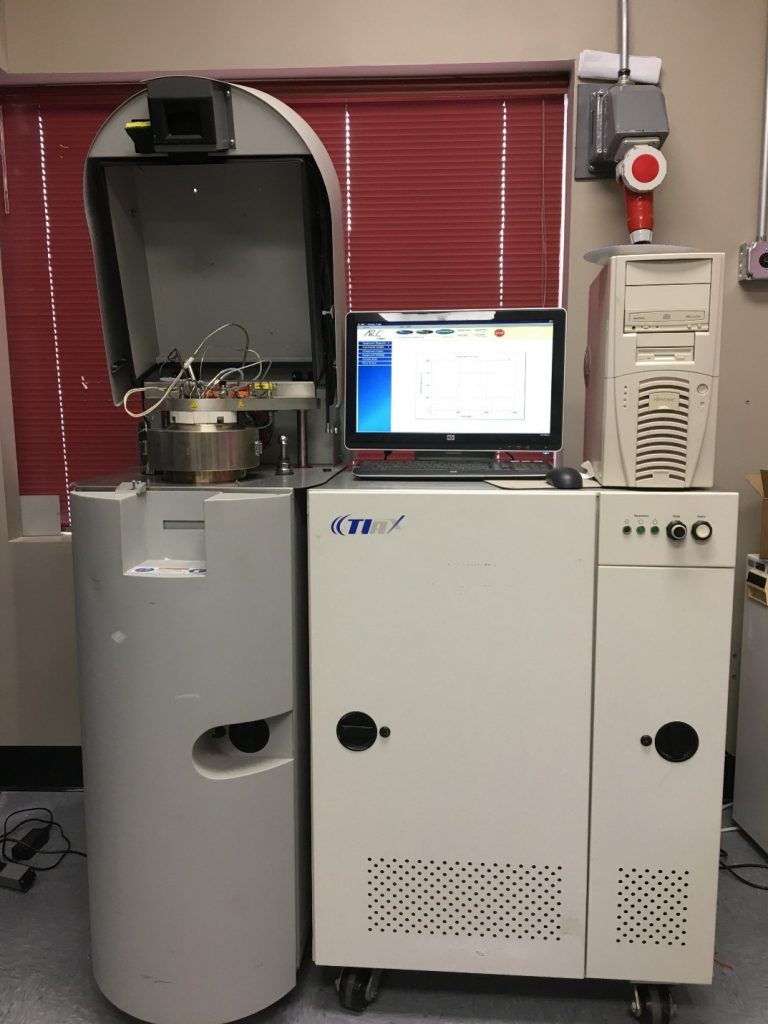

ARC from CSI and ARC 254 from Netzsch Group of Selb, Germany

(High Thermal Inertia)

Onset temperature

Temperature rise rate

Pressure rise rate

Heat of reaction

Amount of gas generated

Vent flow regime

ASTM E1981-98 (2012)e1

Standard Guide for Assessing Thermal

Stability of Materials by Method of

Accelerating Rate Calorimetry (ARC)

Vent Size Package 2 (VSP2) from

Fauske & Associate, LLC, Burr Ridge,

IL USA

(Low Thermal Inertia)

On-site Calorimetry Testing: BSI provides on-site thermal hazard testing services using DSC, ARC®, and VSP2.

Shock Sensitivity Testing: BSI uses a blasting cap test method to characterize materials for shock sensitivity. Test uses about a 15ml sample size and is a Go/No-Go test. This test can also be performed on-site.

ADDRESS

- +1 (978) 677 - 9671

- info@belmontscientific.com

- 210 Stedman Street,Unit 3 Lowell,MA 01851,USA