Contract Research

Battery Technology

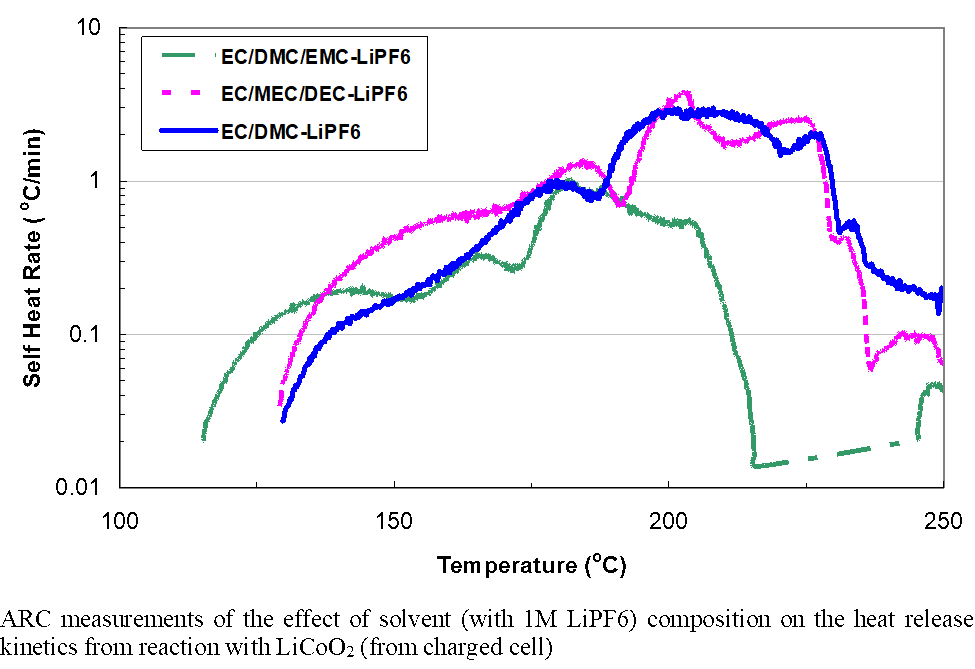

Laboratory is equipped with instruments to handle samples in an inert atmosphere, exhaust gaseous decomposition products, electrochemical characterization of batteries under controlled temperatures, thermal behavior evaluation of battery raw materials, Li-ion cells and battery packs, thermal abuse evaluation, nail penetration and crush testing, pressure drop test and external short circuit test. Related equipment:

Coin cell crimper and pouch cell sealer

Battery cyclers

MBraun glove box

Temperature controlled chambers for shelf life/cycle life testing

Battery test holder (Pressure and non-pressure) for ARC and VSP2

Carver hydraulic press for crush and nail penetration test

Process Development & Organic Synthesis

Our expertise in process chemistry and chemical safety makes us uniquely qualified to develop hazardous processes. Some of these processes include; alkylation, hydrogenation, nitration, and azide chemistry etc. BSI provides services for chemical process development such as; optimum process temperature, reactant addition, mixing, neutralization, and heat transfer. We also provide small scale (up to 0.5L batch) specialty chemical synthesis.

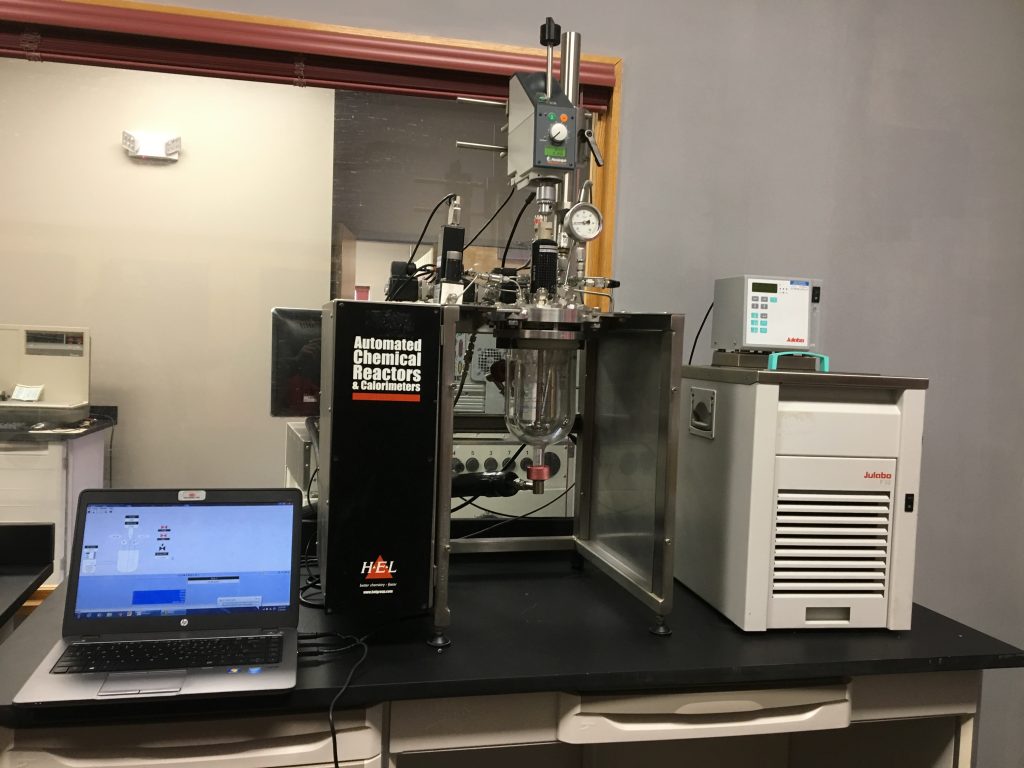

Our laboratory is equipped with various computer-controlled reactors (100ml to 500ml capacity) with heating, cooling, stirring, and gas purging capabilities. Synthesis could be carried out at ambient pressure to pressures as high as 2000 psi. Some of our equipment is a follows:

- Automated chemical reactor and calorimeter (Simular) by Hazard Evaluation Laboratory (HEL). Heating/cooling (-20C to 200C), stirring, and 0.5L capacity.

- AutoMATE II reactor system by HEL (8 Stainless Steel reactors, each independently controlled).

- Chemglass jacketed 0.5L glass reactor with stirring

- Buchi rotavapor R215

ADDRESS

- +1 (978) 677 - 9671

- info@belmontscientific.com

- 210 Stedman Street,Unit 3 Lowell,MA 01851,USA